5S Training

In today's rapidly increasing business world, increasing workplace productivity and effectively managing resources is a critical factor for success. In this regard, 5S Training , one of the fundamental principles of Lean Manufacturing, stands out as a crucial tool for increasing order and efficiency in the workplace.

What is 5S?

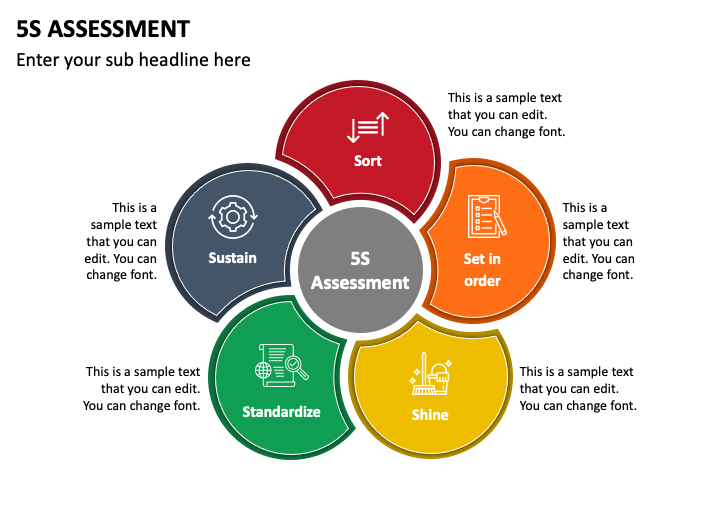

The 5S System is a systematic way to organize workplaces by eliminating waste, improving flow, and minimizing the number of processes whenever possible. It employs five principles: Seiri (Sorting), Seiton (Organization), Seiso (Cleanliness), Seiketsu (Standardization), and Shitsuke (Discipline). Toyota Motor Company pioneered these principles and has increased efficiency in its manufacturing facilities.

Benefits of 5S Application Training

- Increases Work Efficiency: The 5S System optimizes workflow by reducing workplace disorganization and waste. Arranging equipment in a specific order ensures quick availability of materials. This, in turn, increases work efficiency and allows processes to run more quickly and efficiently.

- Reduces Costs: A more organized work environment minimizes material and time losses. Reducing waste in the workplace lowers material purchasing costs and provides a cost advantage for the business.

- Improves Employee Safety: The principles of 5S implementation aim to maintain a clean and orderly workplace. This increases occupational safety standards and ensures that employees work in a safe environment.

- Increases Workplace Motivation: Cleanliness and order increase employee satisfaction with the workplace. This increases motivation and makes employees more committed to their jobs.

- Encourages Continuous Improvement: 5S Training principles focus on continuous improvement. Employees are encouraged to continually improve workplace processes and increase efficiency. This ensures continuous improvement in the workplace.

- Increases Customer Satisfaction: An orderly and effective work environment improves product and service quality. Offering customers more reliable and high-quality products increases customer satisfaction and strengthens a company's competitive advantage.

- Streamlines Workflow: 5S ensures that equipment, tools, and documents in the workplace are organized in a specific order. This streamlines workflow and ensures the efficient use of resources.

- Reduces Human Errors: Order and standardization reduce human errors. Having everything in a specific order prevents misplacement or omissions, which minimizes workplace errors.

- Encourages Innovation: A more organized work environment allows employees to be more relaxed and creative. This fosters innovation in the workplace, allowing new ideas to emerge.

- Improves Work Culture: Implementing 5S fosters an orderly and efficient work culture. This creates better communication, collaboration, and a sense of responsibility in the workplace, which positively impacts the overall work atmosphere.

5S Implementation Training provides businesses with a sustainable competitive advantage. A work environment aligned with these principles contributes to optimizing business processes and increasing the company's overall efficiency.

Why Is It Important in the Workplace?

When implemented correctly, 5S is a springboard for success in the global economy. Implementing a 5S system in the workplace is important because it can enable work to be done more efficiently. For example, when employees consistently work to clean and organize their workspaces, work processes can flow more efficiently. When organizations recognize the need to be proactive in reducing waste, regardless of its form—wasteful movement, waiting time, or step in the process—they can begin to maximize the benefits of 5S implementation.

5S in Six Sigma

Implementing 5S is a methodology often used in conjunction with Six Sigma, a process improvement methodology that aims to identify and eliminate problems. 5S can help create a clean, orderly, and productive work environment conducive to Six Sigma efforts.

There are several ways to use 5S in Six Sigma:

- Improvement projects: The 5S System can be used as a tool to identify and eliminate waste and inefficiencies in business processes. By organizing the work environment and eliminating unnecessary items, it can be easier to identify areas for improvement and focus on the most important issues.

- Defect Prevention: A clean and well-organized work environment can help reduce the risk of errors and defects in work processes. By eliminating distractions and ensuring necessary tools and equipment are easily accessible, it can be easier to maintain focus and attention to detail.

- Process mapping: 5S can be used as a tool to visualize and document business processes. By creating a clear and logical layout of the work environment, it can be easier to define material and information flows and identify areas for improvement.

- Standardization: 5S can be used to create and implement standard procedures for maintaining a work environment. This can help ensure consistent and predictable processes, which can increase efficiency and reduce the risk of errors.

Overall, 5S manufacturing training can be a valuable tool for organizations using Six Sigma to improve their business processes. By creating a clean, organized, and productive work environment, it can be easier to identify and eliminate defects and inefficiencies, and continuously improve the effectiveness and efficiency of business processes.

5S and Lean Manufacturing

5S originated in manufacturing environments. While this visual organization system has been adapted for use in many workplaces, including warehouses, offices, and hospitals, many manufacturing facilities continue to utilize 5S. 5S is often particularly beneficial when combined with other Lean practices.

Every employee in the manufacturing plant is taught which 5S tasks to perform as part of their daily job, making the system sustainable in the long run.

The 5S implementation training we offer at Lean Model goes beyond simply explaining why order, cleanliness, and efficiency are important in workplaces. This training provides participants with a detailed understanding of how to understand, implement, and sustain 5S principles, helping them develop skills to reduce waste and optimize processes in their workplaces. Beyond simply being a regulatory tool, 5S implementation transforms business culture, ensuring sustainable success and empowering businesses to achieve competitive advantage.

Would you like to get information about 5S training?

Fill out the form and we will inform you. You will be informed shortly by our Lean Model customer representative.

En öncelikli hedefi, Yalın dönüşüm danışmanlığına daha farklı bir bakış açısı kazandırmak üzerine, İş dünyasının tüm sektörlerinde, yalın dönüşüm ve operasyonel mükemmellik uygulamalarını stratejik öncelikler ve hedeflerle buluşturarak doğru çözümlere hızlı ulaşım için rehberlik etmektir.

|

Karlıktepe Mah,Fahri Korutürk Cad. No:25/7,34870 Kartal / İSTANBUL |

|

E-Posta

|

|

Telefon

|