APQP Training

In today's increasingly competitive global marketplace, businesses must ensure customer satisfaction to survive and succeed. Ensuring customer satisfaction is crucial for ensuring new products meet customer expectations and are produced to the desired quality. APQP training aims to enhance participants' knowledge and skills by teaching them how to create and implement control plans, ensuring products meet customer expectations and requirements, and ensuring they are delivered on time and at the lowest cost.

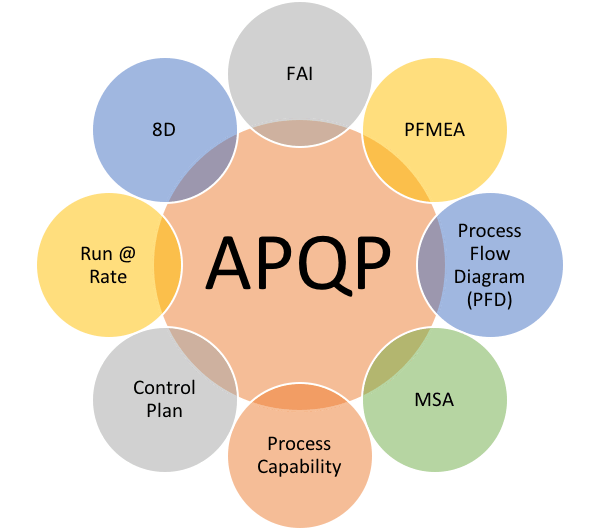

To ensure that new products meet customer expectations and are produced to the desired quality, businesses must adopt the APQP (Advanced Product Quality Planning) approach. APQP is an approach used to plan, implement, and control quality during the development and launch of a new product.

Advanced Product Quality Planning (APQP) Implementation

APQP is a dynamic process consisting of a pre-planning phase and five concurrent phases. Once initiated, the process is never completed and generally operates in the Plan-Do-Check-Act (PDCA) cycle. This cycle is a quality management approach championed by W. Edwards Deming. Each phase is aligned with analytical risk discovery tools and techniques. The goal of APQP is to prevent late failure in product and process development.

Sections of APQP

Part 1: Preliminary Planning – The APQP process begins with assumptions, concepts, and background information. During this phase, areas where significant changes are expected are identified using library knowledge and standard working practices. The outputs from this section are used to introduce Part 1, the Plan and Define phase.

Part 2: Planning and Definition – This part focuses on connecting customer expectations, wants, and needs to requirements. Developing the Plan determines the deliverables to ensure satisfactory product quality. Resource planning includes process and product assumptions. Additionally, a list of key design and reliability objectives is created.

Part 3: Product Design and Development – This phase focuses on product design and development. Design Review includes refining geometry, design specifications, tolerances, and special features. Design validation through prototypes and testing is a key part of this phase.

Chapter 4: Process Design and Development – Exploring the manufacturing techniques and measurement methods used to transform the design engineer's vision into reality is the primary focus of this chapter. Process Flow Diagrams, Process FMEA, and Control Plan Methodology are just a few of the tools used in this phase.

Part 5: Product and Process Validation – This phase involves verifying the process quality and volume capabilities that are the focus of the work. Statistical Process Control (SPC), Measurement Systems Analysis (MSA), and Process Capability Studies are introduced in this phase. The Part Approval Process (PPAP) is prepared for delivery, and production begins once approved.

Section 6: Feedback Assessment and Corrective Action – This section provides learning from the ongoing production process. It covers topics such as RPN reduction, corrective actions (both internal and external), the Eight Problem-Solving Disciplines (8Ds), and capturing relevant information for future use.

APQP Training Purpose

APQP training helps businesses correctly implement the APQP approach. Through this training, participants gain knowledge and skills in the following areas during the new product development and launch process:

- Fundamentals of the APQP approach

- Product design and development

- Production processes and planning

- Quality control and assurance

- Customer expectations and management

APQP training provides businesses with the following benefits:

- It ensures that new products meet customer expectations and are produced at the desired quality.

- It makes the product development and deployment process more efficient.

- Increases customer satisfaction.

- It reduces costs.

The goal of APQP training is to ensure that businesses correctly implement the APQP approach to ensure new products meet customer expectations and are produced to the desired quality. This goal can be further explained through the following sub-objectives:

- Teaching the basics of the APQP approach: It is necessary to teach the participants what the APQP approach is, how it is applied and what benefits it provides.

- Teaching the product design and development process: It is necessary to teach the participants the stages of the product design and development process, the points to be considered in these stages and the tools used.

- Teaching production processes and planning: It is necessary to teach the participants the process of designing and planning production processes, the points to be considered in this process and the tools used.

- Teaching quality control and assurance: It is necessary to teach participants the basics of quality control and assurance, quality control and assurance practices and how to use these practices.

- Teaching customer expectations and management: It is necessary to teach participants the process of understanding and managing customer expectations and methods of collecting and using customer feedback.

APQP training utilizes a variety of methods to achieve these sub-objectives. These methods may include presentations, discussions, group work, case studies, and practical exercises. Furthermore, this training is an important tool for businesses to ensure that new products meet customer expectations and are produced to the desired quality. Through this training, businesses can streamline their product development and deployment processes, increase customer satisfaction, and reduce costs.

Advanced Product Quality Planning (APQP) training, in conjunction with our company's consulting, training, and coaching services, opens the door to raising the quality standards in your business processes. This comprehensive training, drawing on our company's areas of expertise, aims to contribute to your business's success.

With our consulting services, we review your business processes and identify potential areas for improvement. Our training programs strengthen your competitive advantage by enhancing your knowledge and skills in quality management. Furthermore, with our coaching services, we help you effectively implement this new knowledge and strategies.

Ultimately, APQP training is key to initiating a quality-focused transformation within our company's comprehensive service offering. To improve the success of your business processes and stand out in the industry, we're ready to guide you. We wish you success!

Would you like to get information about APQP training?

Fill out the form and we will inform you. You will be informed shortly by our Lean Model customer representative.

En öncelikli hedefi, Yalın dönüşüm danışmanlığına daha farklı bir bakış açısı kazandırmak üzerine, İş dünyasının tüm sektörlerinde, yalın dönüşüm ve operasyonel mükemmellik uygulamalarını stratejik öncelikler ve hedeflerle buluşturarak doğru çözümlere hızlı ulaşım için rehberlik etmektir.

|

Karlıktepe Mah,Fahri Korutürk Cad. No:25/7,34870 Kartal / İSTANBUL |

|

E-Posta

|

|

Telefon

|