MSA Measurement Systems Analysis

Obtaining accurate and reliable measurements in production and quality control processes is a fundamental goal of every business. Inaccurate or inconsistent measurements not only reduce product quality but can also lead to production delays, financial losses, and customer dissatisfaction. This is where MSA Measurement Systems Analysis comes into play. MSA is a statistical method used to determine the reliability and accuracy of measurement systems and the measuring devices used.

Benefits of MSA Measurement Systems Analysis

MSA is a critical tool in manufacturing and quality control processes. Proper implementation of MSA can provide numerous benefits. Some of these benefits include:

Improving Product Quality: MSA helps improve product quality by identifying errors and variations of the measurement system and minimizing these errors.

Improvement of Manufacturing Processes: MSA helps prevent errors and defects in manufacturing processes by identifying them and improving manufacturing processes.

Increasing Customer Satisfaction: MSA also contributes to increasing customer satisfaction by helping to increase product quality and improve production processes.

Reducing Costs: MSA helps reduce costs by preventing errors and defects and improving production processes.

Reducing Errors and Risks: MSA helps reduce errors and risks by increasing the reliability and accuracy of the measurement system.

Other Benefits:

- Increased reliability of products

- Increased production capacity

- Optimization of stock levels

- Reduction in customer complaints

- It also increases competitiveness.

Areas Where MSA Is Applied

MSA is a critical tool in manufacturing and quality control processes. Its applications are extensive and include:

Production: MSA Measurement Systems Analysis is used to verify the calibration and accuracy of all measuring devices and systems within the production line. This ensures that manufactured products meet the required quality standards.

Quality Control: MSA is also used in the quality control processes of manufactured products. Product dimensions, weights, performance, and other characteristics are measured using MSA to verify product compliance with standards.

R&D: MSA is also used in R&D studies. During the development and testing of new products, measurements made with MSA help determine whether the products meet the desired specifications.

Laboratories: MSA is also used in laboratory testing and analysis. The reliability of test and analysis results depends on the MSA verification of the measuring devices and systems used.

Healthcare: MSA is also used in the healthcare sector. MSA is used to check the calibration and accuracy of medical devices used in patient diagnosis and treatment.

Finance: MSA is also used in the financial sector. Measurements made with MSA are used in assessing financial risks and making investment decisions.

Logistics: MSA is also used in the logistics sector. MSA controls the calibration and accuracy of equipment used during product transportation and storage.

At the same time:

- Automotive

- Aviation

- Electronic

- Chemical

- Plastic

- Textile

- It can also be used in food areas.

Stages of MSA Measurement Systems Analysis Studies

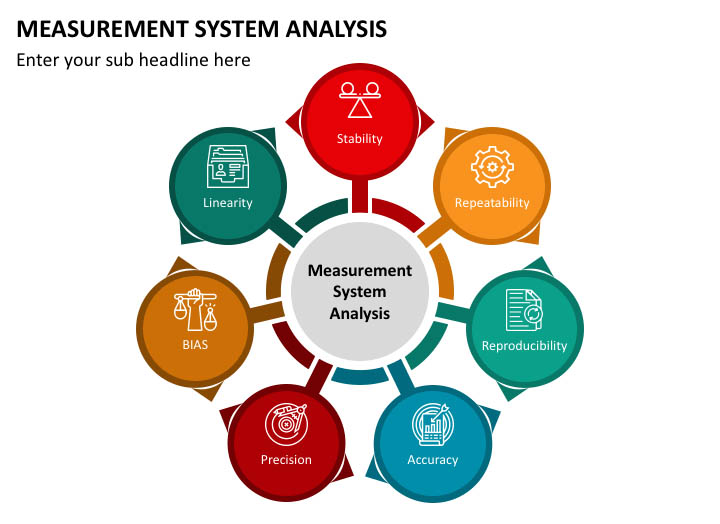

MSA Measurement Systems Analysis studies provide a systematic approach to assessing measurement system performance and making necessary improvements. It consists of five key stages:

Planning: This phase requires defining the measurement system, identifying the attribute to be measured, and clarifying the purpose of the MSA study. This phase determines which questions the MSA will answer and which parameters will be evaluated.

Data Collection: Data is collected on how the measurement system performs under different conditions and with different operators. The data collection plan should be designed to cover all variations of the measurement system.

Data Analysis: Collected data is analyzed using statistical methods. Parameters such as accuracy, repeatability, and stability of the measurement system are evaluated. The acceptable limits of these parameters must be predetermined.

Results Evaluation: The results of the MSA Measurement Systems Analysis are interpreted and necessary improvements are identified. Concrete recommendations are presented regarding which aspects of the measurement system need improvement.

Implementation and Monitoring: Identified improvements are implemented, and the performance of the measurement system is monitored. MSA studies are repeated periodically to ensure continuous improvement of the measurement system.

Success of MSA Studies:

The success of MSA studies depends on the work done during the planning phase and the meticulous execution of data collection and analysis. MSA studies must be conducted by qualified personnel and equipped with appropriate statistical tools.

Statistical Methods Used in MSA

MSA studies use a variety of statistical methods to evaluate the performance of the measurement system. The most commonly used methods include:

Repeatability and Reproducibility Studies: These studies evaluate how different operators measure the same part at different times. Analysis of variance (ANOVA) and R&R plots are used in these studies.

Deviation Study: This study determines how close the mean value of a measurement system is to the reference value. T-tests and control charts are used in these studies.

Linearity Study: This study evaluates how accurate a measurement system is for different measurement values. Regression analysis and linearity graphs are used in these studies.

Stability Study: Evaluates how the measurement system performs over time. These studies use control charts and trend analysis.

Other Methods: Within the scope of MSA studies, other statistical methods such as correlation analysis and factor analysis can also be used.

Method Selection: The statistical method to be used is determined by the type of measurement system, the property to be measured, and the purpose of the MSA Measurement Systems Analysis study. Choosing the right method is critical to the success of the MSA study.

The Future of MSA Measurement Systems Analysis

MSA will become increasingly important as production and quality control processes continue to evolve. In the future, MSA is expected to become more automated and utilize new technologies such as artificial intelligence. The use of MSA will contribute to increased production consistency, customer satisfaction, and reduced production costs.

At Yalın Model, we have a team of experts in MSA. By providing MSA solutions tailored to your business's needs, we can help you optimize your production and quality control processes and produce higher-quality products.

You can contact us for more information about MSA Measurement Systems Analysis and free consultation service.

Would you like to get information about MSA Measurement Systems Analysis?

Fill out the form and we will inform you. You will be informed shortly by our Lean Model customer representative.

En öncelikli hedefi, Yalın dönüşüm danışmanlığına daha farklı bir bakış açısı kazandırmak üzerine, İş dünyasının tüm sektörlerinde, yalın dönüşüm ve operasyonel mükemmellik uygulamalarını stratejik öncelikler ve hedeflerle buluşturarak doğru çözümlere hızlı ulaşım için rehberlik etmektir.

|

Karlıktepe Mah,Fahri Korutürk Cad. No:25/7,34870 Kartal / İSTANBUL |

|

E-Posta

|

|

Telefon

|